PATCH was developed to address a real operational gap: maintaining situational awareness and secure communication for teams operating without reliable infrastructure.

The inventors, Maeve Garigan and Dana De Coster, first worked together in 2015 while supporting US Special Operations units. At the time, Maeve was deploying new technologies with operational teams, and Dana was serving as an Operations Officer overseeing West Coast SEAL elements. Their early collaboration included the deployment of backpackable reconnaissance drones, combining operational need with rapid technical execution.

That experience highlighted a recurring problem: teams lacked a reliable way to maintain awareness of friendly forces and communicate securely when cellular, Wi-Fi, satellites, or legacy radio systems were unavailable or inappropriate.

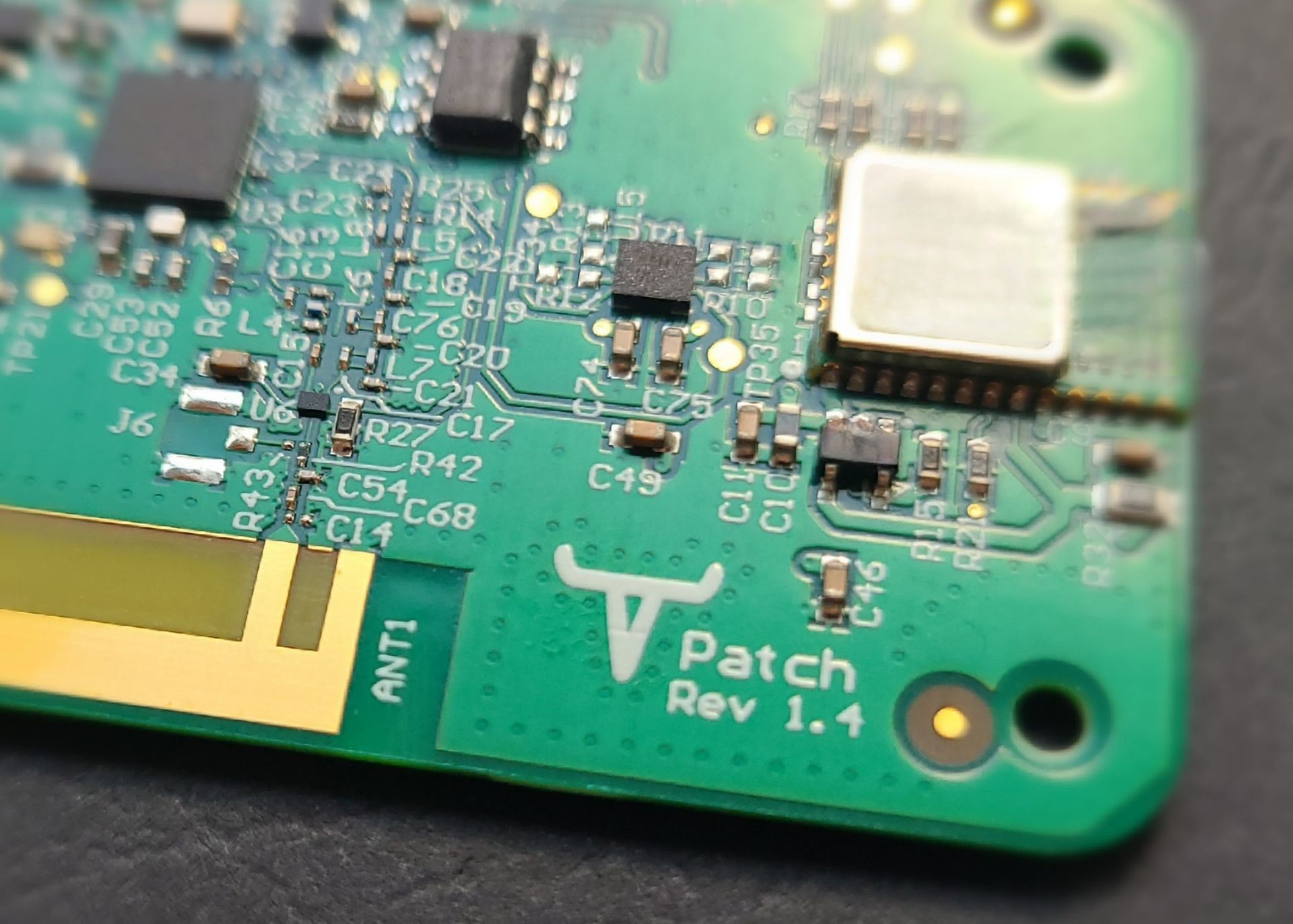

PATCH was initially conceived as a wearable tracking device designed to be lightweight, rugged, and easy to use in the field. The form factor was intentionally a patch-style wearable, integrating seamlessly into existing uniforms and equipment rather than adding another device to manage.

As the concept matured, it became clear that tracking alone was insufficient. Operational feedback pointed to the need for secure, off-grid communication at the tactical level. The system was expanded to support encrypted messaging and data exchange over a self-forming mesh network, independent of external infrastructure.

PATCH pairs with a mobile application that provides a user interface for messaging, location sharing, and status awareness. Communications are protected using AES-256 encryption, and the system is designed without persistent data storage.

Encryption keys are generated at network initialization and are discarded when the network session ends. Location, activity, and message data are not stored on the PATCH device, reducing residual data exposure in the event of device loss.

The first PATCH prototype was designed and built in six weeks for an invite-only military technology demonstration in June 2021. That early prototype demonstrated the core concept: secure, infrastructure-independent situational awareness and communication in a wearable form factor.

PATCH continues to evolve based on real operational requirements, with a focus on reliability, security, and usability under constraint.